Product Introduction

V Series - Zinc Ion Electrochemical Sensor Test Strips

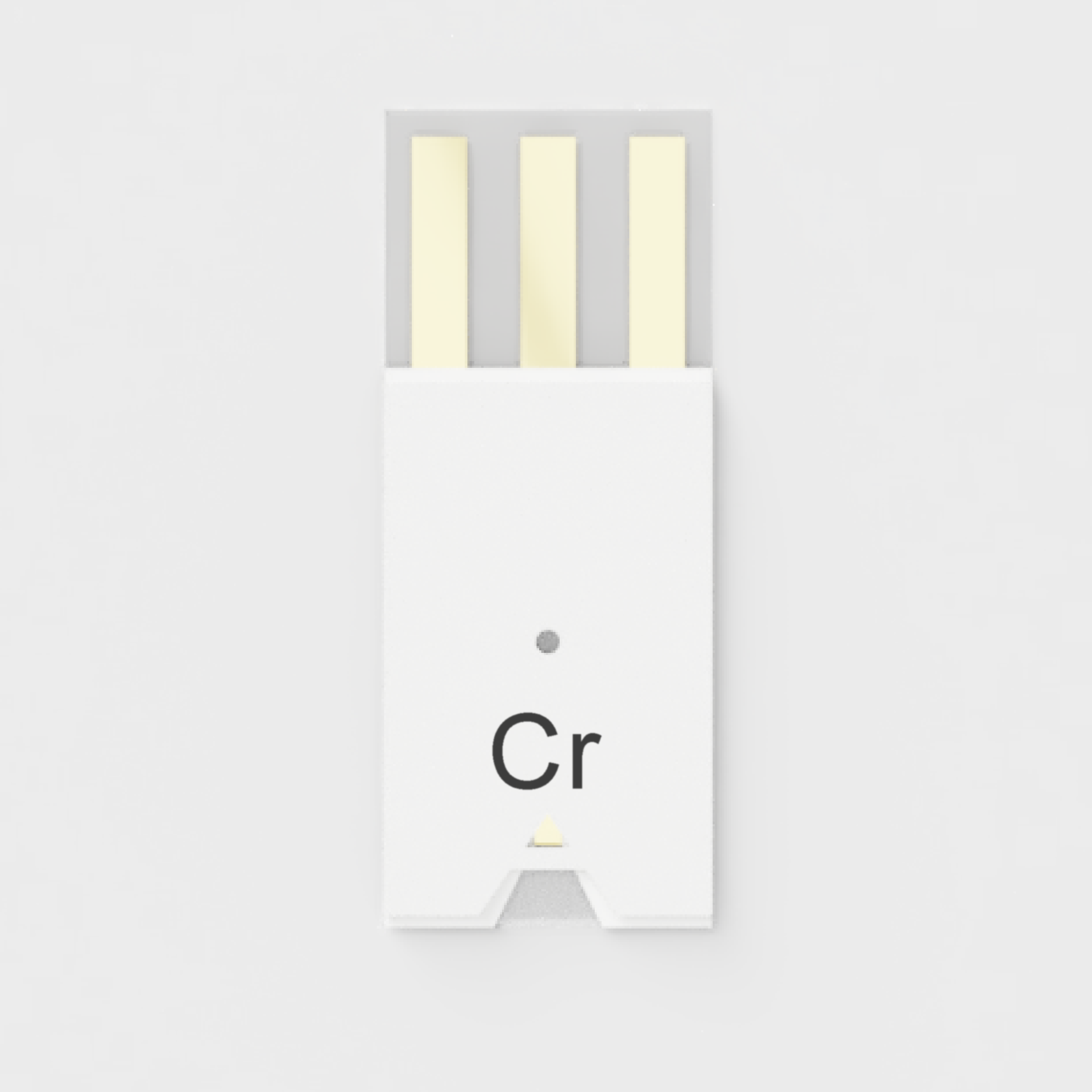

In order to meet the needs of most small and medium-sized factories in Taiwan for self-monitoring of discharged wastewater, Ruizhun has released the V series of products that are applicable to Taiwan's latest effluent regulations for copper, nickel, chromium, and zinc commonly used in electroplating processes. Water quality heavy metal test piece.

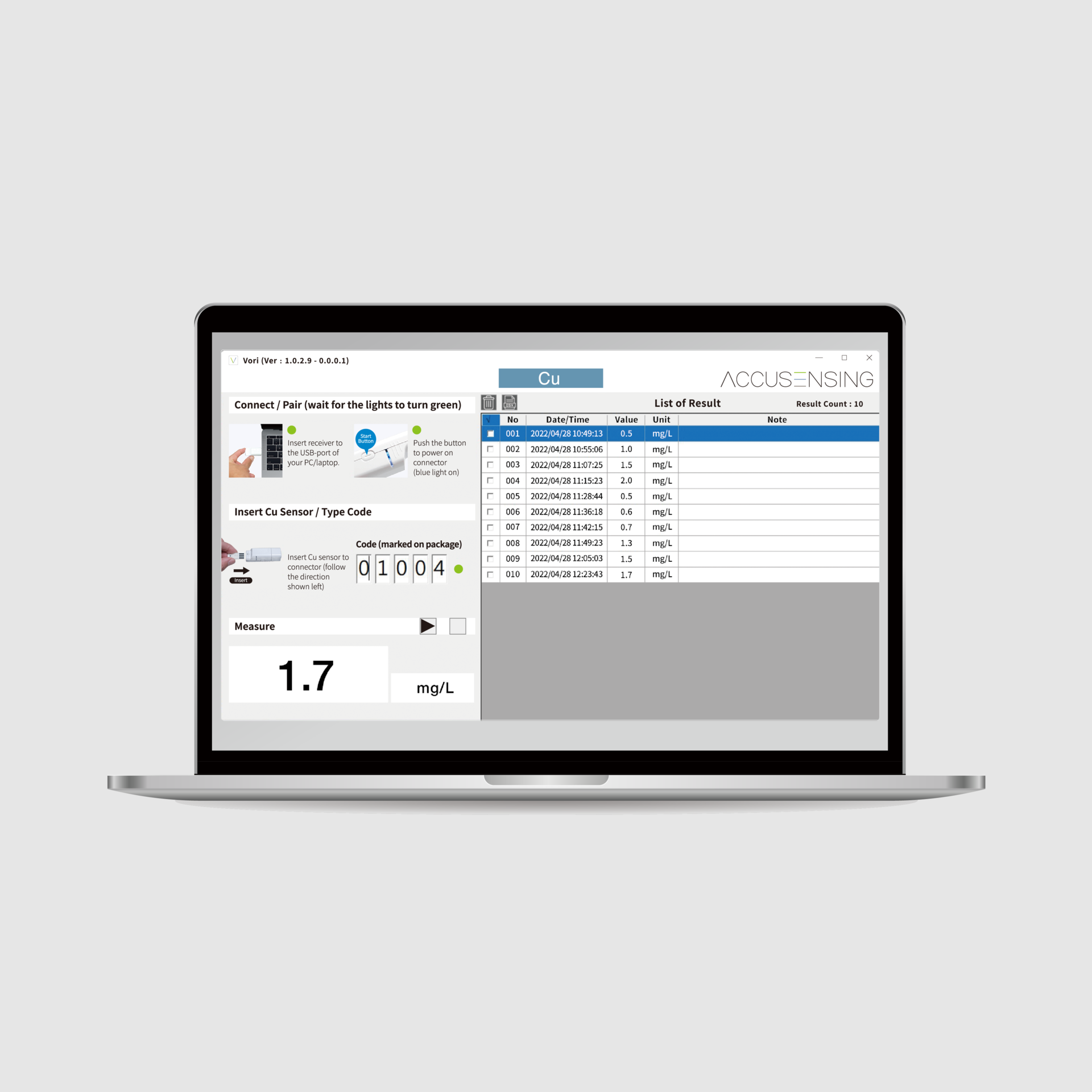

The V series test strips inherit the advantages of the M series electrochemical sensors, which are simple to operate and do not require the addition of chemicals. When used with the electrochemical water quality analysis software VORI, you can quickly obtain digital measurement values and easily control your wastewater discharge.

SPECIFICATION

- model

- Zn-V1550

- Detection species

- Divalent zinc ion

- Quantitative detection range

- 1.5-5.0 mg/L

- Minimum detection limit

- 1.0 mg/L

- Analysis time

95 seconds - Calibration curve calibration method

Exclusive calibration code

Technical Information

Chrome Sensitivity Test Pieces - V Series / M Series - Product Comparison Table

| V Series Zinc Sensitivity Test Pieces Zn-V1550 |

M Series Zinc Sensitivity Test Pieces Zn-M050500 |

|

| Detection concentration range | 1.5-2.0 mg/L | 0.50-5.00 mg/L |

| Calibration curve | Enter the correction code | Calibration-free (calibrated before leaving the factory) |

| Detection time | 95 seconds | 95 seconds |

| Resolution | 0.1 mg/L | 0.01 mg/L |

| Drug addition/pretreatment | Need not | Need not |

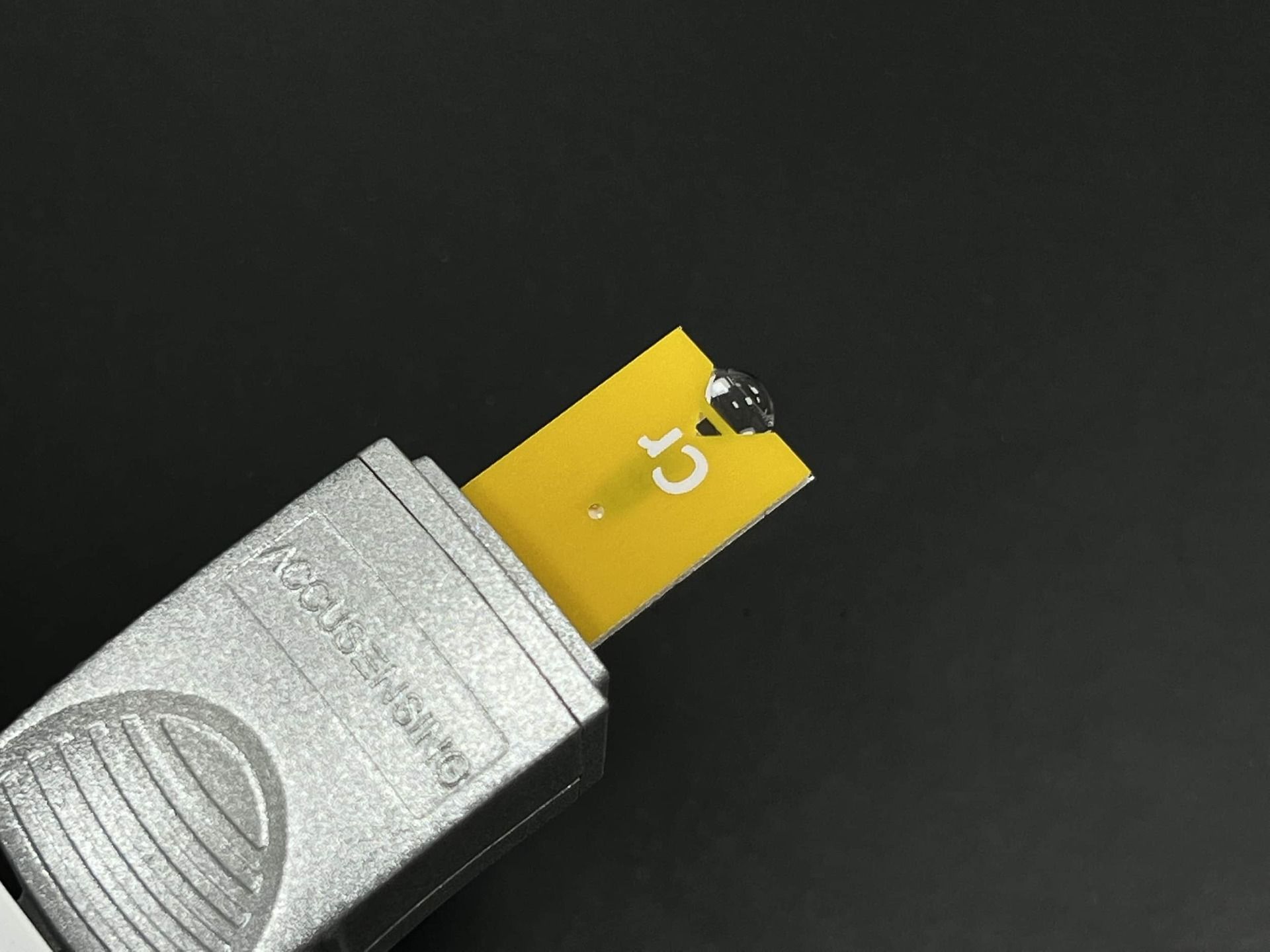

| Required sample volume | 1 drop | 1 drop |

FEATURES

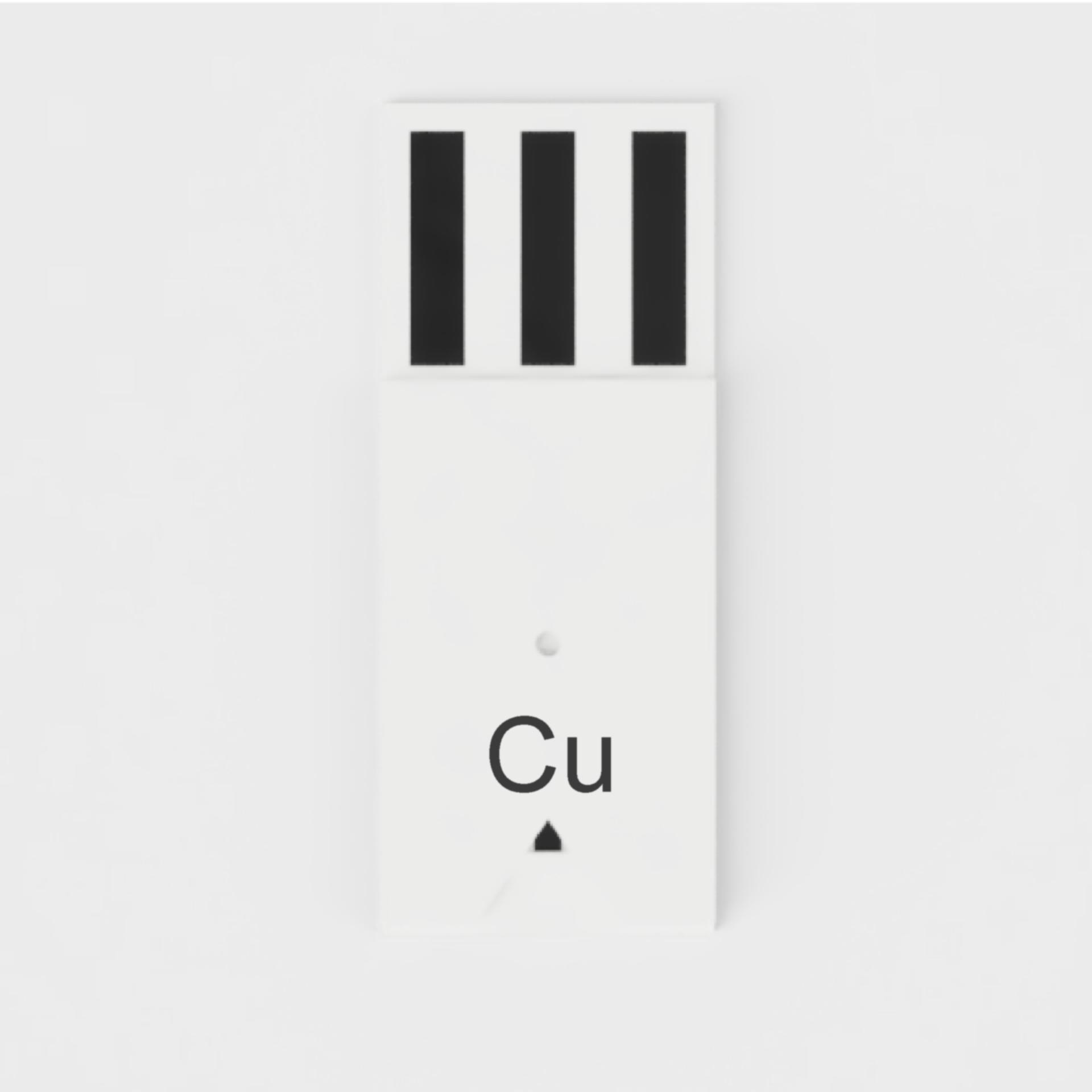

- No need to add pre-treatment reagents, just dip the test piece in the water sample

- No need to build a calibration line

- Equipped with microfluidic reaction tank, which is pre-coated with reaction reagents (non-controlled toxic substances)

- Only one drop of sample required

- Electrochemical three-electrode system detection (non-optical method)

- The material of the test piece is recyclable and will not cause any environmental burden

ACCUSENSING's metal ion sensor improves the existing on-site water quality rapid screening tools/instruments on the market that have no numerical values when detecting heavy metals, require pre-treatment with chemicals, are cumbersome and time-consuming to operate, and are inconvenient to carry. After continuous research and development, improvement, and real factory water sample testing, the product has been adopted by well-known domestic and foreign customers such as the Environmental Protection Administration of the Executive Yuan, Nan Ya Technology, a semiconductor manufacturer under the Formosa Plastics Group, Yongqiang Co., Ltd., a well-known electroplating company in the north, and MAPUA University in the Philippines.