Product Introduction

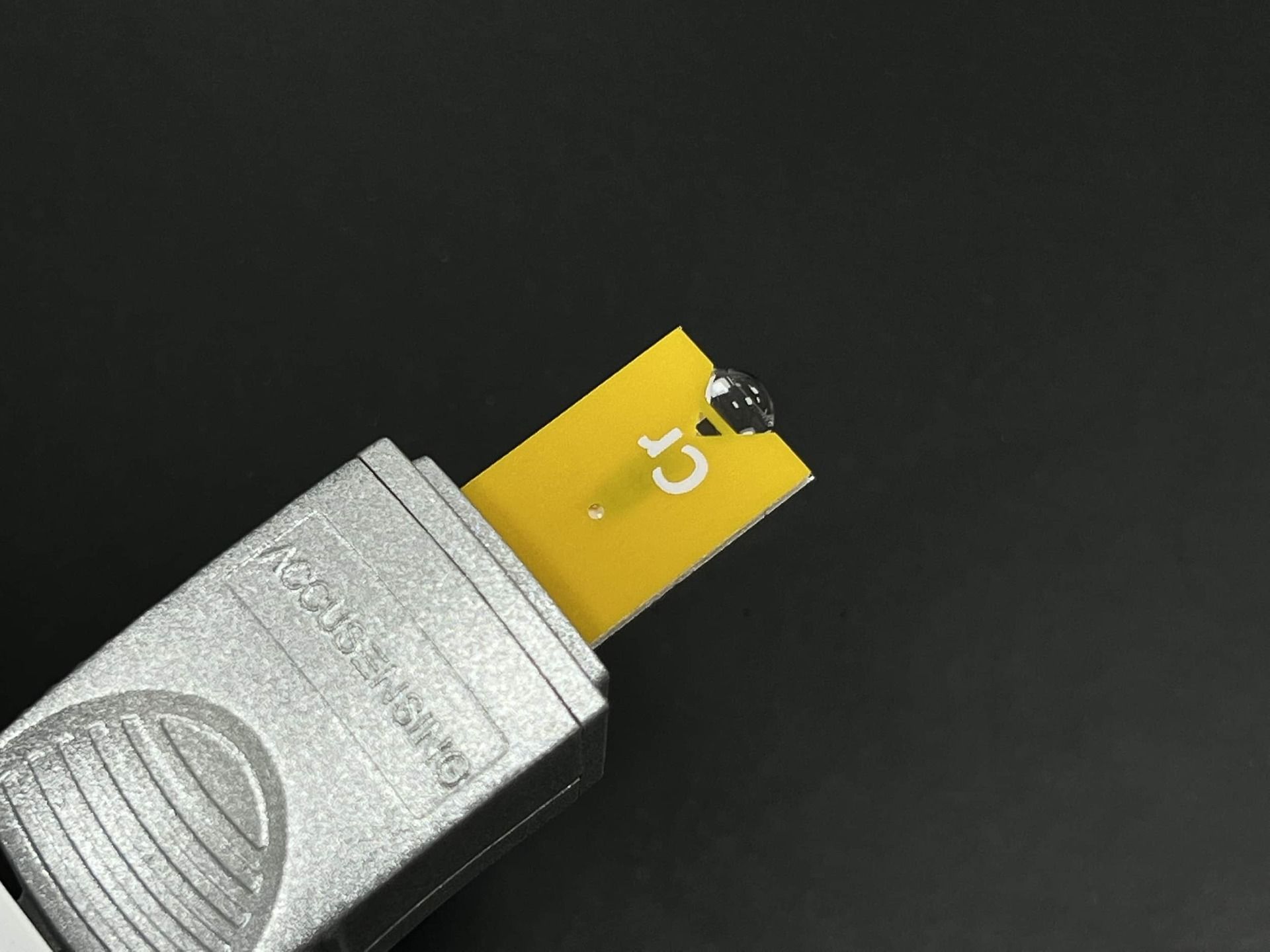

Electrochemical copper ions sensor

The M series test strips introduce key technologies of biomedical blood glucose test strips, integrating electrochemical three-electrode system, microfluidics and drug coating technology on each sensor. Using a consistent production process, the quality of each tube sensor test strip is strictly controlled, and laboratory ppb-level detection can be achieved within a few minutes. With the portable electrochemical metal ion detection system MAS G1, users do not need complicated pre-treatment and calibration procedures, and do not need to worry about sample cross-contamination or interference caused by human operation, and can obtain the most real-time data in a highly efficient way.

SPECIFICATION

- model

- Ni-M001100

Detection species Divalent nickel ion - length

- 30 mm

- width

- 12 mm

- Microchannel volume

- 10 uL

- Calibration line concentration range

- 0.10-1.00 mg/L

- Minimum detection limit

- 0.07 mg/L

- Analysis time

- 123 seconds

Technical Information

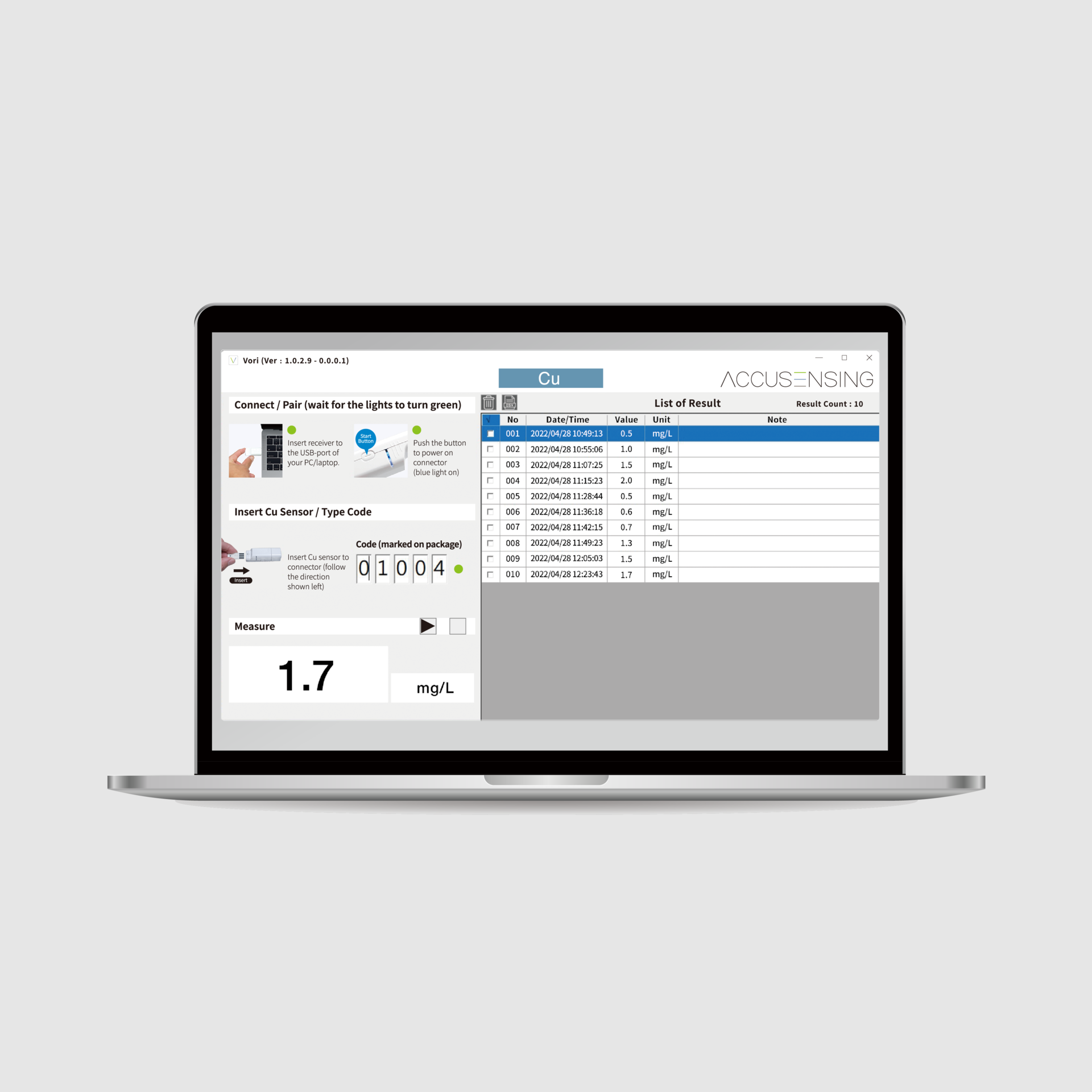

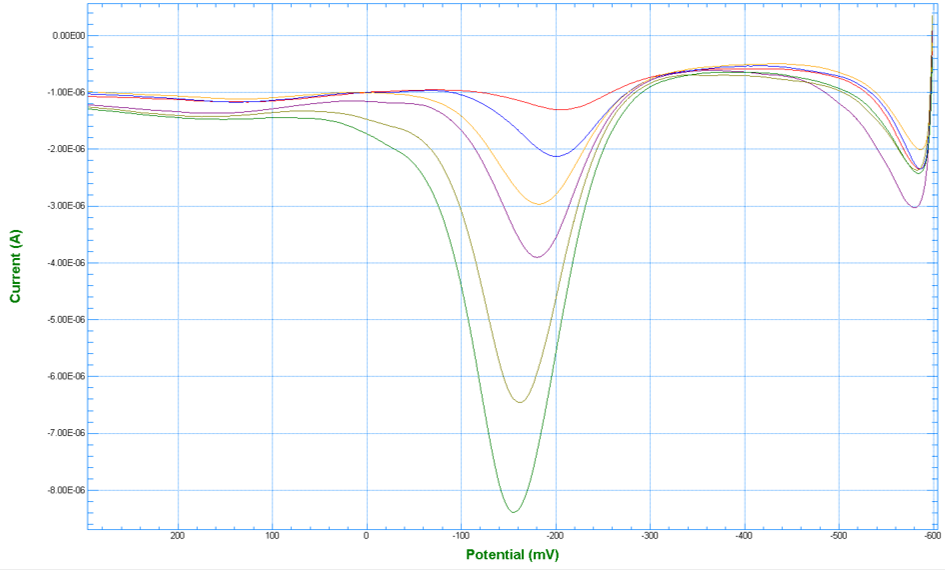

There is a very obvious copper ion current signal near -200 mV. The signal increases with the increase of copper ion concentration. After regression analysis of the current signal intensity and concentration, R2 > 0.99, indicating that this sensor can accurately quantify in real samples.

The quantitative range of Cu-M020300 (0.20-3.00 mg/L) is set for mass production to comply with the current Taiwan industrial effluent control standards. If you have quantitative requirements below 0.20 mg/L or above 3.00 mg/L, please call or write to our company for further discussion.

According to the 2018 "Industrial Wastewater Pollution Prevention and Investigation and Analysis Plan" of the Environmental Protection Administration of the Executive Yuan, the number of heavy metal copper samples in industrial effluents audited by environmental protection units is as high as 3,048 per year, the highest frequency among all regulated heavy metals. Wastewater produced by any industrial field with copper processes, such as electroplating plants, semiconductor technology plants and PCB plants, may contain a certain concentration of copper ions. If the wastewater is not treated carefully, it may be discharged into the surrounding water bodies with the effluent, posing a threat to precious water resources.

Starting from January 1, 2021, the copper control value for domestic industrial effluent water has been tightened by 50% from the original 3mg/L to 1.5mg/L. This amendment not only increases the cost of wastewater treatment for industries, but also poses a severe challenge to the water quality monitoring tools/instruments (colorimetric reagent kits, spectrometers, etc.) used by factory self-management or front-line personnel of environmental inspection units.

Among them, the colorimetric reagent package is the most commonly used self-monitoring method for many small and medium-sized electroplating plants in China. It is characterized by simple operation and low price. Unfortunately, there is no digital display of the measured value. Users can only estimate the approximate measured value by comparing the color card. In our experience of dealing with many factories of this type, we have encountered many factories that use reagent kits for testing. The operators immediately judged that the color did not exceed the emission control standards, but when they sent the samples to the laboratory for AA/ICP testing, they found that they exceeded the standards. Such unintentional mistakes may cause the operators to face large fines and damage their reputation, which is not worth the loss.

FEATURES

- No need to add pre-treatment reagents, just dip the test piece in the water sample

- No need to build a calibration line

- Equipped with microfluidic reaction tank, which is pre-coated with reaction reagents (non-controlled toxic substances)

- Only one drop of sample required

- Electrochemical three-electrode system detection (non-optical method)

- The material of the test piece is recyclable and will not cause any environmental burden

The metal ion sensor of ACCUSENSING Technology has improved the problems of on-site water quality rapid screening tools/instruments on the market that have no numerical values when detecting heavy metals, require pre-treatment with chemicals, are cumbersome and time-consuming to operate, and are inconvenient to carry. After continuous research and development, improvement, and real factory water sample testing, the product has been adopted by well-known domestic and foreign customers such as the Environmental Protection Administration of the Executive Yuan, Nan Ya Technology, a semiconductor manufacturer of the Formosa Plastics Group, Yongqiang Co., Ltd., a well-known electroplating company in the north, and MAPUA University in the Philippines.